Mills Equipment Cleaner

The Pattern 1908 Web Infantry Equipment 1913 states, “Should the equipment become in a dirty or greasy condition, it may be washed, using warm water, soap and a sponge. Then rinse with clean water, and when thoroughly dry apply the cleaner in the manner laid down in the instructions accompanying it. No cleaner may be applied to the equipment unless previously approved by the War Office”

The Pattern 1908 Web Infantry Equipment 1913 states, “Should the equipment become in a dirty or greasy condition, it may be washed, using warm water, soap and a sponge. Then rinse with clean water, and when thoroughly dry apply the cleaner in the manner laid down in the instructions accompanying it. No cleaner may be applied to the equipment unless previously approved by the War Office”

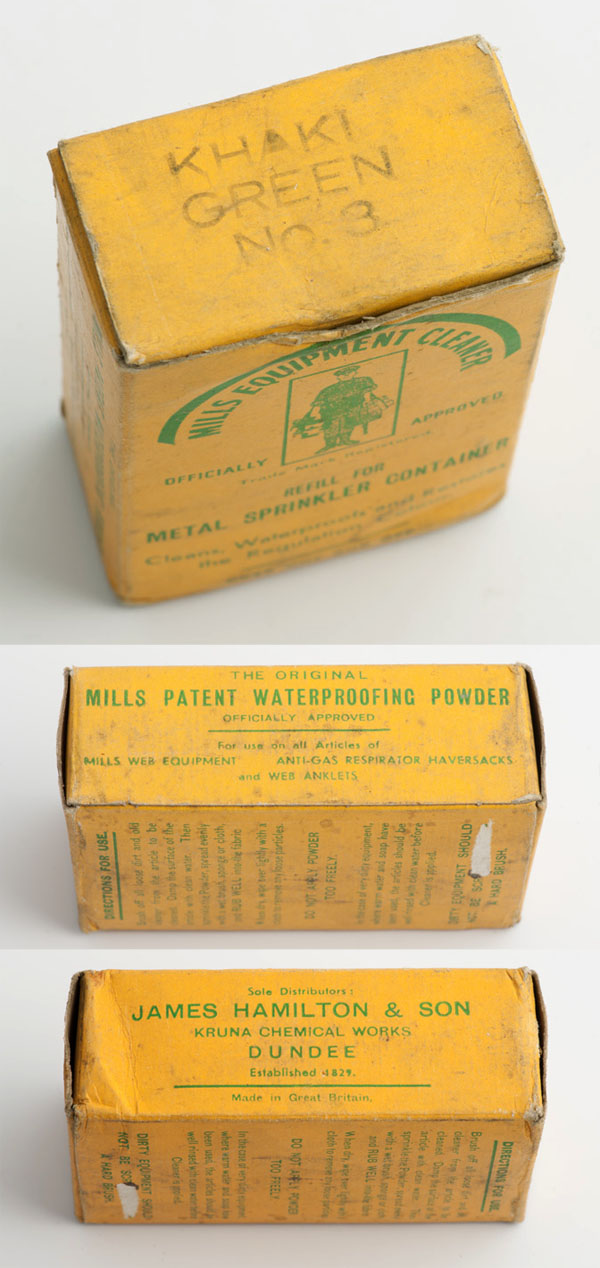

Mills Web Equipment Khaki Cleaner No. 700 was made by James Hamilton and sons of Dundee. Labelled “THE ORIGINAL MILLS PATENT CLEANING POWDER AS OFFICIALLY APPROVED FOR USE ON ALL ARTICLES OF MILLS WEB EQUIPMENT”. It also states that it “Cleans, Waterproofs & Restores THE REGULATION COLOUR OF THE MILLS WEB EQUIPMENT.”

It was a powder of light green shade contained in a cardboard tube capped with metal ends.

A year or so after the introduction of the 1908 Equipment the question arose as to how the equipment could be kept in a clean condition, apart from the usual brushing and light scrubbing with soap and water. Many users were careless and allowed grease and oil off the rifle to come into contact with the equipment which, in spite of drastic scrubbing, discoloured the webbing.

Mr Francis Stevenson was consulted and he, together with his friend James Hamilton of Dundee (this website author thinks this is an error and should state George Hamilton), a Manufacturing Chemist, carried out numerous experiments to produce a ‘Cleaner’ to restore the waterproof properties of the webbing and to renovate the standard Khaki colour after the the articles of equipment had been scrubbed.

They succeeded in producing a powder to be mixed with water for application to the webbing, and the results proved so satisfactory that the ‘Web Equipment Cleaner’ was approved by the Army Council in the year 1910; it remained standard for many years, and at one time during the First World War it was the only renovator allowed to be used on Anti-Gas Respirator Haversacks, the duck from which they were made having to retain its original porosity to air. British Patent No. 24593 was granted to Messrs. Stevenson and Hamilton in 1910. Supplies were put on sale in Army and Navy Canteens in Great Britain and Overseas.

Mr David Hazel formed the Mills Cleaner Company, of City Road, London, E.C., and under his direction sales flourished for some years.

Subsequently, other colours of powder were produced in R.A.F. Blue, Green for Irish Equipment and shades of Grey for Italy and Peru, clearly postwar.

The main interest the M.E.Co. had in the production of a suitable Cleaner was to ensure that the Mills’ reputation did not suffer by the use of pastes or powders which might have a deleterious effect on the webbing. It was known that block forms of cleaner could not be ‘rubbed down’ with water and applied to the fabric to render it waterproof; in fact such a preparation would render fabric liable to water absorption which would have a serious effect on the equipment in storage.

Refill packs for the sprinkle tins were available. Here is illustrated KG 3.

Directions for use.

Brush off all loose dirt and old cleaner from the article to be cleaned. Damp the surface of the article with clean water. Then sprinkle the Powder, spread evenly with a wet brush, sponge or cloth and RUB WELL into the fabric.

When dry, wipe over lightly with a cloth to remove loose particles.

DO NOT APPLY POWER TOO FREELY.

In the case of very dirty equipment where warm water and soap have been used, the articles should be well rinsed with clean water before Cleaner is applied.

DIRTY EQUIPMENT SHOULD NOT BE SCRUBBED WITH A HARD BRUSH.

THE ORIGINAL

MILLS PATENT WATERPROOFING POWDER

Officially Approved

—————–

For use on all Articles of

MILLS WEB EQUIPMENT, ANTI-GAS RESPIRATOR HAVERSACKS and WEB ANKLETS

Photos: David Pratt

This product was available in 1942 and was on the list of approved products in the 1942 Home Guard regulations when KG3 was universally adopted as the only official equipment cleaner colour.

Constable Street still exists in Dundee. Although one side of the street has been removed for new roads there still exist stone-built factory premises, one of which dates to 1828 so it may be possible that the “Kruna Works” building (which we know existed until at least 1942) is still standing.

THE EDINBURGH GAZETTE, SEPTEMBER 11, 1936

Dated at Dundee, this eighth day of September nineteen hundred and thirty-six.

MARY S. STEVENSON.

ELIZA. C. HAMILTON.

Witnesses to the Signatures of Mrs. Mary Singleton Batchelor or Stevenson and Mrs. Eliza Corner Menzies or Hamilton, the Trustees and Executors of the said George Sutherland Hamilton—

EDWARD R. SIMPSON, 12 Bank

Street, Dundee, Solicitor.

ANNIE C. WATT. 12 Bank Street,

Dundee, Typist.

JAMES HAMILTON.

Witnesses to the Signature of the said James Hamilton—

EDWARD R. SIMPSON, 12 Bank

Street, Dundee, Solicitor.

EVELYN D. FETTES, 12 Bank Street,

Dundee, Cashier.

Here follows the text of the 1910 Patent:

No 24,593 A.D. 1910

Date of Application, 22nd Oct., 1910

Complete Specification Left, 24th Apr., 1911 – Accepted, 14th Sept., 1911

PROVISIONAL SPECIFICATION

An Improved Composition for Cleaning and Water-proofing Textile and other Fabrics or Materials.

We, FRANCIS STEVENSON, of Lawside Dye Works, Dyer and Bleacher, and GEORGE SUTHERLAND HAMILTON. of 13, Erskine Street, Manufacturing Chemist, both in Dundee, in the County of Forfar, do hereby declare the nature of this invention to be as follows : –

This invention relates to the manufacture and application of a composition or compound for cleaning and water-proofing textile fabrics, felt, buck-skin and the like, the composition being particularly applicable for treating the web equipments used by the army and territorial forces.

The improved composition is composed of natural or artificial coloured pigments or pigments or colouring matter, powdered soap soluble in water, and a metallic salt or metallic salts, also soluble in water, and the metals of which are capable of reacting with the said soluble soap to form an insoluble soap when the finished composition or cleaner is treated with water.

These ingredients may be mixed in widely varying proportions depending on the colour and nature of the article to be cleaned and waterproofed. For example we find that for certain textile fabrics the following ingredients and proportions are suitable.

Pigment 100 parts by weight.

Soap 4 parts by weight.

Potash alum 12 parts by weight

To apply the composition it is mixed with water to a consistency of cream and is then sponged or brushed on to the fabric or material to be treated whereby the dirt is removed from the said fabric or material and the aqueous mixture penetrates the surface to a certain extent and on drying deposits a coating of insoluble soap and pigment. The coating of insoluble soap is more or less impervious to water and has the effect of waterproofing the said fabric or material to a corresponding extent. The desired colour of the treated and dried fabric or material is obtained by regulating the colour and amount of the pigment or pigments used, or by selecting a suitable metallic salt or salts or by a combination of both methods.

Dayed the 22nd day of October, 1910.

G.F.REDFERN 7 Co.,

15, South Street, Finsbury, E.C., and

10, Gray’s Inn Place, W.C.,

Agents for the Applicants.

Composition for Cleaning and Water-proofing Textile and other Fabrics or Materials.

COMPLETE SPECIFICATION

An Improved Composition for Cleaning and Water-proofing Textile and other Fabrics or Materials.

We, FRANCIS STEVENSON, of Lawside Dye Works, Dyer and Bleacher, and GEORGE SUTHERLAND HAMILTON, of 13, Erskine Street, Manufacturing Chemist, both in Dundee, in the County of Forfar, do hereby declare the nature of this invention and in what manner the same is to be performed, to be particularly described and ascertained in and by the following statement :-

This invention relates to the manufacture and application of a composition or compound for simultaneously cleaning and water-proofing textile fabrics, felt, buck-skin and the like, in one operation, the composition being particularly applicable for treating the web equipments used by the army and territorial forces.

The improved composition is composed of natural or artificial coloured pigment or pigments or coloured matter, powdered soap, soluble in water, and a metallic salt or metallic salts, also soluble in water, and the metals of which are capable of reacting with the said soluble soap to form an insoluble soap when the finished composition or cleaner is treated with water.

These ingredients may be mixed in widely varying proportions depending on the colour and nature of the article to be cleaned and waterproofed. For example we find that for certain textile fabrics the following ingredients and proportions are suitable.

Pigment 100 parts by weight.

Soap 4 parts by weight.

Potash alum 12 parts by weight.

To apply the composition it is mixed with water to the consistency of bream and is the sponged or brushed on to the fabric or material to be treated whereby the dirt is removed from the said fabric or material and the aqueous mixture penetrates the surface to a certain extent and on drying deposits a coating of insoluble soap and pigment or coloured matter. The coating of insoluble soap is more or less impervious to water and has the effect of waterproofing the said fabric or material to a corresponding extent. The desired colour of the treated and dried fabric or material is obtained by regulating the colour or amount of the pigment or pigments or coloured matter used, or by selecting a suitable metallic salt or salts or by a combination of both method.

Having now particularly described and ascertained the nature of our said invention and in what manner the same is performed, we declare that what we claim is :-

1. Cleaning and waterproofing textile and other fabrics and materials in one operation by applying thereto a composition of pigment, powdered soap and metallic salts or salts mixed with water, substantially as described.

2. The improved composition for simultaneously cleaning and waterproofing textile and other fabrics or materials on one operation, consisting of the ingredients mixed substantially in the proportions specified and adapted to be applied in the manner herein set forth.

dated the 24th day of April, 1911.

G.F REDFERN & Co.,

15, South Street, Finsbury, E.C., and

10 Gray’s Inn Place, W.C.,

Agents for the Applicants.

EXTENSION OF PATENT

PATENT No. 24593, A.D. 1910

A New Patent has been granted for a term of three years from the expiration of the original Patent (21st October, 1926), by Order of the High Court.

The Patent Office

12th January, 1927