Kiwi brand

100 years of Kiwi polish 1906 – 2006

The background to this was that in June 1878 William arrived in Melbourne with his parents and his three brothers, who included (Sir) John and Hugh. Three sisters and two more brothers were born in Melbourne. The Ramsays settled at Prahran and on leaving school William joined his father in a real estate business, John Ramsay & Son, which prospered sufficiently to enable his father in 1888 to build for his family a mansion, Clydebank, at Essendon. After the boom broke, John Ramsay was a valuer for the Essendon and Melbourne City councils and for the State Savings Bank of Victoria.

William visited New Zealand and on 2 January 1901 at Oamaru married Annie Elizabeth Meek. Returning to Melbourne he formed a partnership with Hamilton McKellar and established a modest factory at Carlton to manufacture a range of products including disinfectant powder, stove polish, cleanser and boot cream. In 1904 they moved to Elizabeth Street, Melbourne, and next year produced a new boot cream, ‘Mirror’, which was moderately successful.

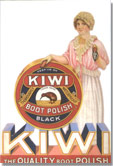

In October 1906 Ramsay & McKellar introduced a boot polish under a new trademark, ‘Kiwi’, in recognition of Annie Ramsay’s origins and by the end of the year they had sold eighty-six gross. Competition remained severe until 1908 when they released ‘Dark Tan’, the first stain polish with the ability to restore, maintain or even alter the colour of leather. Light Tan, Brown, Ox Blood, Black and a patent leather polish quickly followed. People began to appreciate the qualities of KIWI for saddles and leather goods other than footwear and sales began to rise.

Kiwi Shoe Polish was not the first boot polish on the market but what differentiated it was that it also preserved and restored the colour of leather and made shoe ware water resistant. Ramsay began marketing his product in Melbourne. He would load boxes of his polish on his horse and wagon and hawk it to the ranchers in the surrounding countryside. So successful was KIWI, that its popularity spread throughout Australia, based solely on its superior performance.

By 1908, Ramsay began to export to New Zealand and Europe, especially to Britain. As leather shoes and boots became more affordable to the masses, the demand for a product that could polish them quickly, efficiently and easily grew.

In 1909 William sold one hundred gross in Sydney. Other colours followed and within three years ‘Kiwi’ had become a leading brand name throughout Australia. McKellar left the company and Ramsay, trading as sole proprietor of Kiwi Polish Co., moved into larger premises in Elizabeth Street. In 1912, William Ramsay’s father, John Ramsay, arrived by clipper in Southampton. Business in England commenced with a staff of three. William followed in 1913 to explore the potential of the European market. Sales grew dramatically and KIWI began to sell in all states of the Commonwealth. Within three years of the introduction of stain polish, KIWI was a leading Australian brand.

Having just begun to taste the fruits of success, William Ramsay died of cancer on 4th September 1914 at the age of 47, shortly after his return to Australia. He never got to fully appreciate just how successful his formula for KIWI shoe polish was going to be.

The First World War had started and trench warfare brought dreadful trench conditions that were a breeding ground for the most appalling foot rot. The only thing that protected the masses of men in the trenches from this crippling condition was dry feet and the one way to ensure this was with Kiwi’s water resistance.

In accord with a wish expressed in William’s will, the British and Australian companies amalgamated in 1916 as The Kiwi Polish Co. Pty Ltd with William’s father as chairman of directors and his brother James, who had been running the English branch, as joint managing director. The company claimed to have made in 1917 the earliest advertising film in existence, a two-hundred foot, six-minute promotion. Kiwi’s first brand advertising was screened in the UK showing one of the first KIWI tans.

The English factory was working at top pressure; plant and production were radically revised and modernized to meet the dramatically increasing demands of the military. In 1917, one single order from the British Army alone totalled 10,000 gross (1.4 million). Wherever Allied troops were stationed, KIWI was demanded.

By 1918 ‘Kiwi’ had sold thirty million tins of and by 1924 it was distributed in fifty countries. A large modern factory at Richmond, Melbourne and more extensive English headquarters at Ballards Lane, Finchley, London, were built.

The momentum given to sales and distribution by wartime pressures continued without slackening into the roaring twenties. Civilians had money to spend on leisure and amongst other things, began to purchase the polish that gave such glitter to their army´s leather equipment.

On 3 March 1924 William’s father, John, died at Clydebank. William’s widow took over as chair of the company (1924-33) and in 1928 their elder son John (1904-1966), who had joined the company in 1921, became managing director. Their younger son (Sir) Thomas (b.1907) also joined the company as consulting chemist in 1926 and in 1956 became managing director, with his brother John as chairman.

The big crash of 1929 swept through western economies. Many factors combined caused the only decline in KIWI sales figures in the company’s history: on the one hand, the world-wide economic depression, more and more macadamised roads with better drainage, the preference for shoes instead of boots, and the passing, in the main, of the horse with its saddlery and harness, brought changes to peoples habits. On the other hand, production had become costly and quality was hard to maintain. KIWI knew only too well that its reputation at home and abroad had been built on quality and this was not negotiable. New machinery and scientific methods were devised to streamline production and minimize rising costs. Laboratory control of raw materials was instituted to ensure consistent quality and reduce losses. Temperature control was introduced, and checks on the printing and fit of KIWI’s five colour tins began. New accounting systems were adopted which gave immediate and reliable statistics on stocks, sales and costs throughout the world. Kiwi survived the Depression and continued to grow in the post -depression years.

The big crash of 1929 swept through western economies. Many factors combined caused the only decline in KIWI sales figures in the company’s history: on the one hand, the world-wide economic depression, more and more macadamised roads with better drainage, the preference for shoes instead of boots, and the passing, in the main, of the horse with its saddlery and harness, brought changes to peoples habits. On the other hand, production had become costly and quality was hard to maintain. KIWI knew only too well that its reputation at home and abroad had been built on quality and this was not negotiable. New machinery and scientific methods were devised to streamline production and minimize rising costs. Laboratory control of raw materials was instituted to ensure consistent quality and reduce losses. Temperature control was introduced, and checks on the printing and fit of KIWI’s five colour tins began. New accounting systems were adopted which gave immediate and reliable statistics on stocks, sales and costs throughout the world. Kiwi survived the Depression and continued to grow in the post -depression years.

The mid thirties saw an accelerating economic recovery throughout the world and sales began to rise again. In 1934, to avoid tariff barriers in the export business a factory was opened in Auckland and a manufacturing agreement was established in France. In 1937 to meet the expanding market in Eastern Europe the company opened a factory in Warsaw, Poland. In the Pacific area large shipments of polish were being sent from Melbourne to the Malay States and China. American Marines stationed in Shanghai became acquainted with the product and introduced it to the United States on their return. The Kiwi business was thriving.

Then World War II began. The Blitzkrieg was unleashed on Poland and within days of the outbreak of war the Warsaw branch had been destroyed by fire and the manager and all his family perished during the German occupation. The French factory was commandeered by the occupying army although the manager and his wife escaped to England.

Then World War II began. The Blitzkrieg was unleashed on Poland and within days of the outbreak of war the Warsaw branch had been destroyed by fire and the manager and all his family perished during the German occupation. The French factory was commandeered by the occupying army although the manager and his wife escaped to England.

In England, the Ealing factory was bombed but did not suffer major damages. On the positive side of the ledger, despite material shortages common to all manufacturers, KIWI was again called on to meet the demands of the armed forces. As the American correspondent, Walter Graeber wrote for TIME from the Tobruk trenches in 1942, “Old tins of British-made KIWI polish lay side by side with empty bottles of Chianti. A story indicative of the rise in global significance of shoe polish is told by Jean Williams a New Zealander who lived in Japan during the Allied Occupation after World War II. She relates how the American soldiers were finding the dullness of their shoes to be a handicap when trying to win the affections of Japanese girls, “When the Commonwealth Forces arrived in Japan with their boots polished to a degree not known to U.S. forces, GI´s were more conscious than ever of their feet. The secret was not spit and polish, but in superior Australian boot polish. In fact, it became so sought after that Kiwi was the most highly rated bartering commodity, commanding many cartons of Yankee Cigarettes for one can of Kiwi.” Soldiers returning from the war continued to use the product creating such a demand that a few years after the cessations of hostilities, Kiwi finally cracked the American market by opening a manufacturing plant in Philadelphia.

It was obvious that the successful outcome of the war combined with tremendous social, economic and political changes were surely to be followed by great challenges and great opportunities in peaceful consumer economies. Kiwi was poised to ride this trend. In 1946, under the direction of John and Tom Ramsay, plans were made for development and expansion: new machines were designed, new products added to the range and a whole new system of raw material testing was developed in the laboratories.

During the ’50s new manufacturing plants opened in Britain followed by India, France, Canada, South Africa, Spain and Pakistan.

During the ’50s new manufacturing plants opened in Britain followed by India, France, Canada, South Africa, Spain and Pakistan.

By 1967 the KIWI brand became so big and its product range so diverse, that all KIWI companies were brought together under one umbrella: KIWI INTERNATIONAL.

A merger in 1981 of two long established Australian companies, Nicholas International Ltd and the Kiwi Polish Company Pty Ltd and formed Nicholas Kiwi.

In 1984 Kiwi was acquired by Consolidated Foods Corporation, which in turn changed its name to SARA LEE.

In 1991 the UK division of Sarah Lee acquired the Reckitt & Colman United Kingdom shoe care business, including its export business from the United Kingdom (the relevant Australian and New Zealand trade marks being assigned to Sara Lee’s Australian subsidiary, Kiwi Brands Pty Ltd). Reckitt & Colman’s USA shoe care businesses were at the same time acquired by Kiwi Brands Inc, another Sara Lee subsidiary. The brands acquired by SL/HPC UK were Cherry Blossom, Meltonian, Properts, Wrens and Magix; Reckitt & Colman retained, however, the Nugget brand (not recently sold in the United Kingdom), and its shoe care businesses in many countries of Asia, Africa and Latin America and some European countries, notably Spain. The sale contract includes a non-competition clause, lasting for three years, after which Reckitt & Colman would be free to re-enter the United Kingdom market. The total paid for the United Kingdom and the USA transactions represented almost entirely trade marks and goodwill. Certain stock was acquired, and a limited range of manufacturing equipment, in particular a liquid (angle neck) filling line, a jar line for creams, a dye line, and mixing tanks and other processing equipment for liquid and cream polishes. This equipment was transferred to Sara Lee’s K&M Candles plant at Honley in Yorkshire, but one of the main products sold under the Cherry Blossom brand, paste polish, was manufactured on Sara Lee’s existing equipment together with the Kiwi paste polish. Reckitt & Colman continued to manufacture polishes under contract to Sara Lee for six months following the merger at its unit in Hull; this unit has subsequently been closed, and the remaining equipment sold or disposed of throughout the Reckitt & Colman group.

In 1991 the UK division of Sarah Lee acquired the Reckitt & Colman United Kingdom shoe care business, including its export business from the United Kingdom (the relevant Australian and New Zealand trade marks being assigned to Sara Lee’s Australian subsidiary, Kiwi Brands Pty Ltd). Reckitt & Colman’s USA shoe care businesses were at the same time acquired by Kiwi Brands Inc, another Sara Lee subsidiary. The brands acquired by SL/HPC UK were Cherry Blossom, Meltonian, Properts, Wrens and Magix; Reckitt & Colman retained, however, the Nugget brand (not recently sold in the United Kingdom), and its shoe care businesses in many countries of Asia, Africa and Latin America and some European countries, notably Spain. The sale contract includes a non-competition clause, lasting for three years, after which Reckitt & Colman would be free to re-enter the United Kingdom market. The total paid for the United Kingdom and the USA transactions represented almost entirely trade marks and goodwill. Certain stock was acquired, and a limited range of manufacturing equipment, in particular a liquid (angle neck) filling line, a jar line for creams, a dye line, and mixing tanks and other processing equipment for liquid and cream polishes. This equipment was transferred to Sara Lee’s K&M Candles plant at Honley in Yorkshire, but one of the main products sold under the Cherry Blossom brand, paste polish, was manufactured on Sara Lee’s existing equipment together with the Kiwi paste polish. Reckitt & Colman continued to manufacture polishes under contract to Sara Lee for six months following the merger at its unit in Hull; this unit has subsequently been closed, and the remaining equipment sold or disposed of throughout the Reckitt & Colman group.

Following a Competition Commission enquiry concerned about domination of the shoe care market Sarah Lee were required to sell the Cherry Blossom brand which is now being manufactured and marketed by Grangers International Ltd, Alfreton, UK.

In the 2000’s a category expansion from shoe polish to foot comfort led to the development of 3 main segments: Business & Casual, Fashion & Style, Active & Sports, aimed at changing the perception that consumers and shoppers have of the shoecare category. New package design and way of merchandising have become much more attractive and eye catching that makes shopping easy and friendly.

In the 2000’s a category expansion from shoe polish to foot comfort led to the development of 3 main segments: Business & Casual, Fashion & Style, Active & Sports, aimed at changing the perception that consumers and shoppers have of the shoecare category. New package design and way of merchandising have become much more attractive and eye catching that makes shopping easy and friendly.

Today, KIWI is sold and marketed in almost 200 countries around the world. With several state of the art new product innovations, KIWI remains the world´s number one shoe care brand.

SC Johnson said it is buying Sara Lee Corp.’s shoe care business, including the venerable Kiwi brand, for $328 million, as Sara Lee continues to shed non-food segments.

The companies announced the deal, expected to close by mid-2011, also includes Sara Lee’s shoe accessory lines Bama International and Kiwi Kleen. Sara Lee said the business had sales in fiscal 2009 of $315 million based on exchange rates at the time. The food and consumer products maker has shed several of its non-food units as it looks to focus on its more-profitable businesses such Hillshire Farms meat and Senseo coffee.

Sara Lee also announced plans to sell a cleaning products division in Australia and New Zealand for about $50 million, and earlier in December it closed the $1.6 billion sale of its body care and European detergent segments to Unilever NV. With the binding offer from SC Johnson, Sara Lee has lined up deals to sell virtually all of its household and body care business.

Privately held Johnson makes household products under brands including Pledge, Glade, Goddards, Mr Muscle, Duck, Windex and Ziploc.

The Kiwi trade marks held variously by Kiwi Products (UK) Limited, Sadlers Court, Yateley, Camberley, Surrey GU17 7RU; Kiwi Products (UK) Limited, Brumwill Road, London W5 1DT; Kiwi Products (UK) Limited, Parkwood Industrial Estate, Bircholt Road, Maidstone, Kent; Kiwi France S.A., Boulevard Industriel, Sotteville-les-Rouen, France, were assigned to Kiwi European Holdings B.V. of Vleutensevaart 100, 3532 AD UTRECHT, Netherlands, in 1999. Title for all Kiwi trade marks passed to S.C. Johnson & Son, Inc., 1525 Howe Street, Racine, Wisconsin 53403, USA in April 2011.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|